Healthy Buildings, Better Care: Piloting Building Performance Evaluations in Manitoba Long-Term Care Facilities

Please join us in-person or virtually for a presentation and panel discussion

RRC Polytech is hosting a knowledge sharing event focused on strengthening collaboration between health and building sectors to improve long-term care facility performance and enhance resident well-being through evidence-based strategies.

This event, presented in-person and virtually via Zoom, will share findings from a recent applied research project examining Building Performance Evaluations (BPEs) in long-term care environments, followed by a panel discussion.

It is intended for professionals across health care, facilities management, design, policy, and research who are interested in improving outcomes in long-term care environments.

DATE:

Thursday, January 29, 2026

TIME:

2:00 p.m. to 3:30 p.m. CST

IN-PERSON VENUE:

RRC Polytech Notre Dame Campus, 2055 Notre Dame Avenue, Winnipeg

Building A – Room A406 (click for campus/parking map)

VIRTUAL ACCESS:

Via Zoom: Link will be provided upon registration

ALL PARTICIPANTS ARE KINDLY ASKED TO REGISTER AT THE LINK BELOW:

ABOUT THE EVENT

Buildings impact more than the environment: they also have a major influence on the health, wellness and comfort of the people who occupy or work in them. It is evident that many facilities perform very differently than intended. Unfortunately, these building performance problems often are neither identified nor addressed.

The COVID-19 pandemic’s disproportionate impact on residents in long-term care exposed serious vulnerabilities in the design and day-to-day operation of these types of facilities. There is a clear need to rethink how long-term care environments are planned, delivered and managed.

Join RRC Polytech’s Building Efficiency Technology Access Centre (BETAC) and Department of Nursing to explore Building Performance Evaluations (BPEs): what they are, how they work, and how they can support better outcomes for long-term care residents and healthier, more productive work environments for staff.

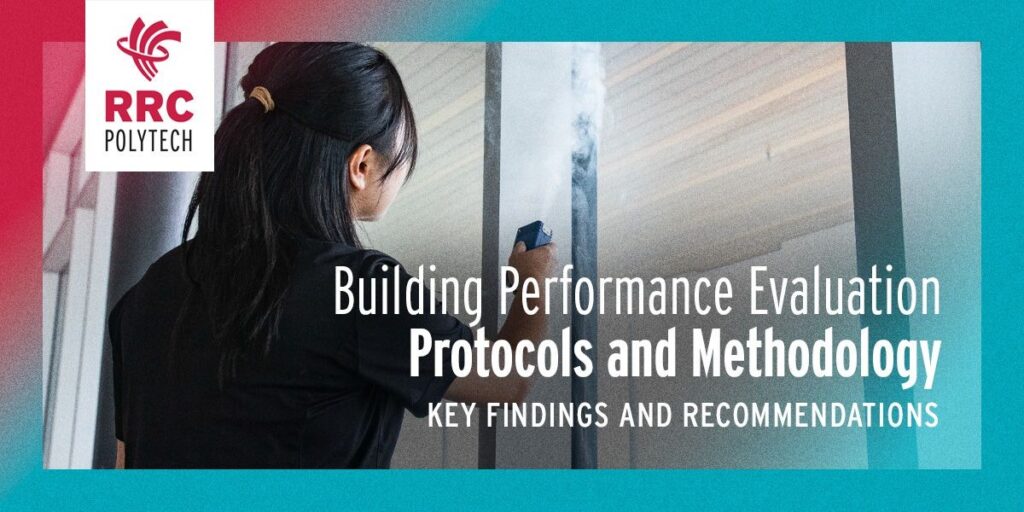

You’ll hear key findings and recommendations from a BETAC-led project that developed practical BPE tools tailored to the long-term care context, including results from a pilot of these tools in six Manitoba long-term care homes.

The event concludes with an expert panel and audience Q&A focused on how governments, owners/operators, health care professionals and the building industry can use BPEs to:

- make better, evidence-based decisions about how to improve building operation and maintenance practices

- guide investments in the design, construction and retrofit/renovation of long-term care facilities to maximize the health and wellness of residents and staff

EVENT AGENDA

Welcoming and Opening Remarks

Alireza Kaboorani, Ph.D.

Director | Building Efficiency Technology Access Centre (BETAC) | Research Partnerships & Innovation | RRC Polytech

Shauna Mallory-Hill, Ph.D. M. Arch B.E.S.

University of Manitoba | Faculty of Architecture | Associate Dean, Research | Associate Professor, Department of Interior Design

An Introduction to Building Performance Evaluations (BPEs)

Learn what a BPE is, how it works and why it should be (but seldom is) a standard part of new construction and major retrofit or renovation projects in long-term care facilities and other buildings.

Ken Klassen, C.E.T.

President | Infotechnika

Lesson Learned: BPE Pilot in Manitoba Long-Term Care Homes

Discover the key findings and resulting recommendations from BETAC’s development of tools for BPEs in long-term care homes and the results from piloting them in six Manitoba facilities.

Chang Liu

Research Technologist | Building Efficiency Technology Access Centre (BETAC) | Research Partnerships & Innovation | RRC Polytech

Jennifer L. Morin, R.N. M.N. C.A.E.

Nursing Instructor/Researcher | School of Health Sciences | Department of Nursing | RRC Polytech

Panel Discussion + Audience Q and A

Hear panelist reflect on the findings of RRC Polytech’s BPE research in the long-term care sector and discuss topics such as:

- What next steps should be taken to avoid building performance problems that negatively impact residents and staff?

- Should BPEs become a mandatory requirement for new and renovated facilities?

- How do we increase collaboration between professions that design, build or renovate and operate these facilities and the health care professionals who manage and operate them and serve their residents?

- What are the greatest opportunities (and barriers) to creating healthier indoor environments Manitoba’s long-term care sector?

Moderator:

Shauna Mallory-Hill

University of Manitoba

Panelists:

Jerald Peters

ft3 Architecture Landscape Interior Design

Craig Doerkson

Shared Health – Soins Communs

Sue Vovchuk

Long-Term and Continuing Care Association of Manitoba

Closing Remarks

Optional In-person Tour

Following the event, join a tour of RRC Polytech’s Interdisciplinary Health and Community Services Simulation Centre

MEET THE SPEAKERS

Shauna Mallory-Hill

Dr. Shauna Mallory-Hill, Associate Professor at the University of Manitoba’s Faculty of Architecture, has more than 25 years of experience teaching and researching building systems, universal and sustainable design, as well as building performance evaluation.

A major focus of her research is on how sustainably designed environments impact human health and productivity.

Mallory-Hill’s building evaluation work has been presented internationally and published in several journals and books including Enhancing Building Performance published by Wiley-Blackwell.

Alireza Kaboorani

Alireza Kaboorani has been serving as the Director of the Building Efficiency Technology Access Centre at RRC Polytech since November 2019.

With over 25 years of experience, he has excelled in planning and spearheading research initiatives in diverse academic and industrial settings.

His areas of expertise encompass building envelope, building science, and the development of advanced building materials and biomaterials.

Ken Klassen

Ken Klassen of Infotechnika is a Winnipeg-based engineering technologist with more than four decades of experience advancing the performance and sustainability of homes, buildings and communities in Manitoba, across Canada, and internationally.

He first became involved in Building Performance Evaluations (BPEs) in 2008. As part of a Canadian team, Ken help assess green building projects across the country and benchmarked the results against leading projects worldwide.

Ken has played a key role in supporting RRC Polytech’s Building Efficiency Technology Access Centre (BETAC) applied research to pilot the use of of BPEs in Manitoba’s long-term care facilities.

Jerald Peters

Jerald is passionate about healthcare design, starting with his graduate thesis on seniors and long-term care housing two decades earlier.

As a principal and the Healthcare Lead at ft3, Jerald advances projects focused on wellness and evidence-based outcomes, strongly advocating that design should improve the lives of those it impacts, and shifting the philosophy away from sustaining lives to enhancing them.

He is a regular attendee and presenter at healthcare conferences and contributes to white papers on topics related to long-term care, acute care, and staff retention.

Craig Doerkson

Craig is the Executive Director of Capital, Clinical Engineering & Facilities Management for Manitoba’s healthcare coordinating agency Shared Health. In this role he is responsible for leading the provincial multi-year planning of all capital, supporting project delivery and setting the standards for provincial FM operations.

Craig is the Immediate Past President of the Canadian Healthcare Engineering Society, and an active member of several Canadian Standards Association subcommittees including the HVAC, Medical Gas Standard, Z8003 Research and Post Occupancy Evaluation, Z8004 Long Term Care Operations and IP&C and the new Z8008 Assessment of Health Care Facilities Services and Building Systems.

He has continued to pursue learning and challenging himself following his B.S. in Energy Systems Engineering he obtained his Professional Engineer designation, a Masters in Facility Management, CFM (IFMA), CEM (AEE) and CHES’ CCHFM designation.

Sue Vovchuk

Sue Vovchuk has over 30 years of experience working with seniors in Manitoba in both frontline and leadership roles. She brings extensive knowledge of public housing, home care, long term care, supportive housing, personal care homes, and assisted living.

A committed and compassionate leader, Sue has built strong relationships with all levels of government and Manitoba’s five Provincial Health Authorities.

As Executive Director of the Long Term Care Association of Manitoba, she is passionate about building partnerships that strengthen current and future care environments for seniors and looks forward to collaborating with provincial, national, and international partners.

Jennifer L. Morin

Jennifer Morin (Otto) is a Manitoba-born registered nurse whose work and studies have taken her across urban, rural, and remote communities throughout the province. She holds a Bachelor of Nursing and a Master of Nursing from the University of Manitoba, as well as a Certificate in Adult Education from Red River College Polytechnic.

Jennifer’s academic and professional work focuses on advancing ecoliteracy within nursing education.

She collaborates with interdisciplinary partners to integrate planetary health into nursing curricula and within Canada’s public health care system — strengthening the profession’s capacity to address climate-related health challenges.

Chang Liu

Chang Liu is the Research Manager at the Building Efficiency Technology Access Centre (BETAC) within Red River College Polytechnic in Winnipeg.

Specializing in building performance and thermal efficiency, she has led significant applied research projects focused on building envelope durability, moisture management, and indoor air quality (IAQ).

For this project, she works in collaboration with the Nursing Department. She manages IAQ data collection, sensor-based analysis, and the identification of performance gaps to recommend design and operational improvements.

These findings were presented at the 2025 Canadian Gerontological Nursing Association Biennial Conference and the 2025 Association of Regulated Nurses of Manitoba Conference.