RRC Polytech’s partnership with Les Verts Living continues to produce success

Innovative hydroponic growing system now in use at the Paterson Globalfoods Institute (PGI) promotes sustainability and offers solutions to offset rising grocery costs

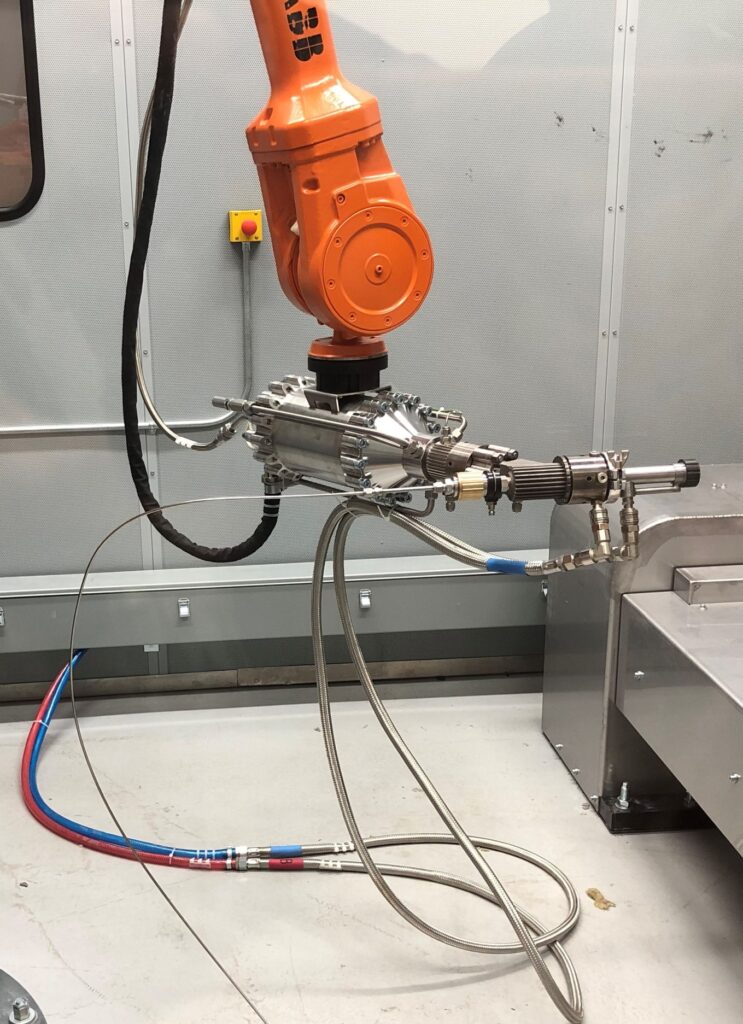

Les Verts Living originally partnered with RRC Polytech to help develop a prototype of its innovative soil-free and pesticide-free hydroponic growing system called the Terrace Pro – taking advantage of the resources and expertise available at the College’s Technology Access Centre for Aerospace and Manufacturing (TACAM), Prairie Research Kitchen (PRK), and Building Efficiency Technology Access Centre (BETAC).

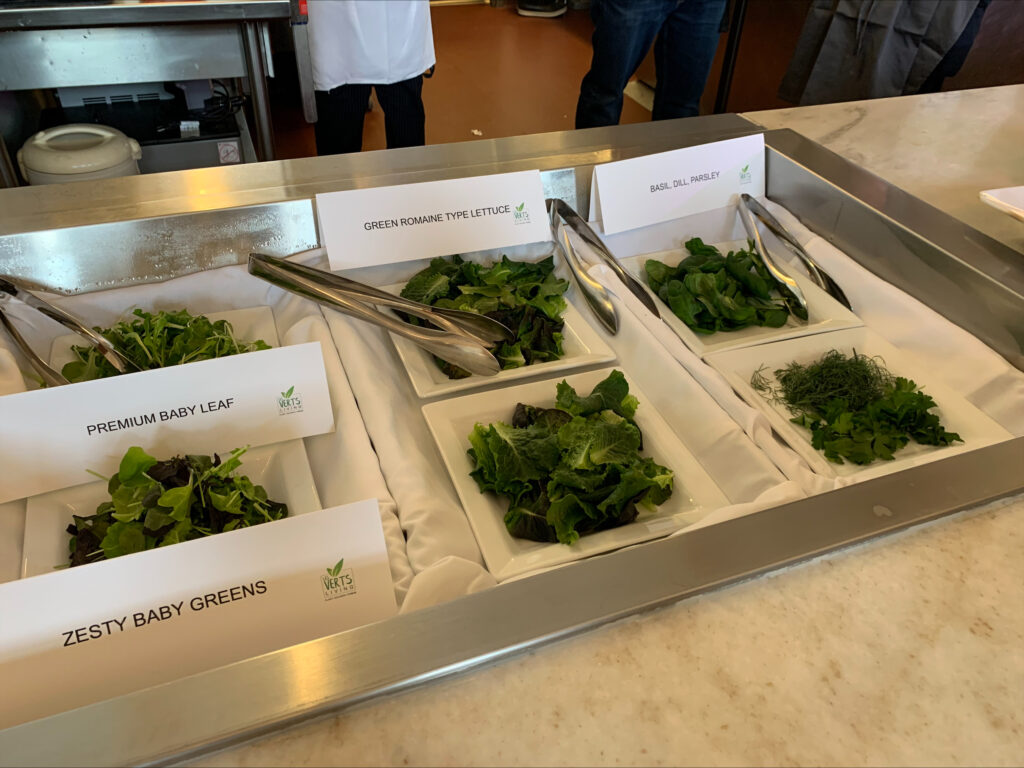

Now with its final product on the market, Les Verts Living is extending the partnership by sharing one of its Terrace Pro units with RRC Polytech to support Culinary Arts students with access to fresh, gourmet produce while they pursue their education. Housing the unit at the Paterson Globalfoods Institute (PGI) will also allow the PRK team to continue researching how to optimize its performance in a commercial setting while developing recipes that highlight the delicious living lettuce, fragrant herbs and hyper-nutritious microgreens and baby greens produced in the Terrace Pro.

“Through our technology, facilities and expertise, the College is uniquely positioned to bring these types of project ideas to life for our industry partners while training the workforce of tomorrow,” said Fred Meier, President and CEO of RRC Polytech. “This project demonstrates the power of partnership and the value of applied research in propelling our province’s economy forward.”