RRC Polytech named a top research college in Canada – leading annual research rankings in innovative solutions and partnerships

Led by a high volume of industry and community partnerships and innovative solutions resulting from completed applied research projects, RRC Polytech has once again been designated a top research institution in the country. Released earlier this week, Re$earch Infosource’s annual ranking of the country’s top 50 research colleges, reinforces RRC Polytech’s leadership role in the innovation ecosystem and its commitment to helping create economic prosperity for all Manitobans through collaboration.

“These current rankings reflect RRC Polytech’s collaborative approach and industry and community relationships are resulting in practical solutions for our partners,” said Jamie Wilson, Vice President, Indigenous Strategy, Research and Business Development at RRC Polytech.

RRC Polytech is the only post-secondary in Canada that integrates research into its Indigenous Strategy portfolio, underscoring its unique commitment to social innovation and Indigenous growth alongside its strong industry focus. The data outlined in Canada’s Innovation Leaders 2025 suggests that local businesses are responding and eager to work together on projects that tackle complex global challenges.

RRC Polytech ranked first among Canada’s medium-tier colleges in completed research projects with 158 and second in total research partnerships with 150. Total industry research income jumped 21.7 percent in fiscal 2024, indicating an increasing trust among businesses in the Polytech’s reputation for consistency and productivity.

“Regardless of the size or scope of the project – from entrepreneurs in search of support to launch and grow their business idea to established enterprises looking to integrate AI, adopt automation or explore transitioning to low carbon – Manitobans can count on our technology, facilities, and expertise to provide affordable and effective problem-solving,” said Wilson.

The applied research activities that connect staff, faculty, and students across all of RRC Polytech’s campuses are orchestrated by its Research Partnerships & Innovation (RPI) enterprise. RPI oversees an ever-expanding suite of leading-edge facilities and resources and coordinates projects that seek groundbreaking new processes and products.

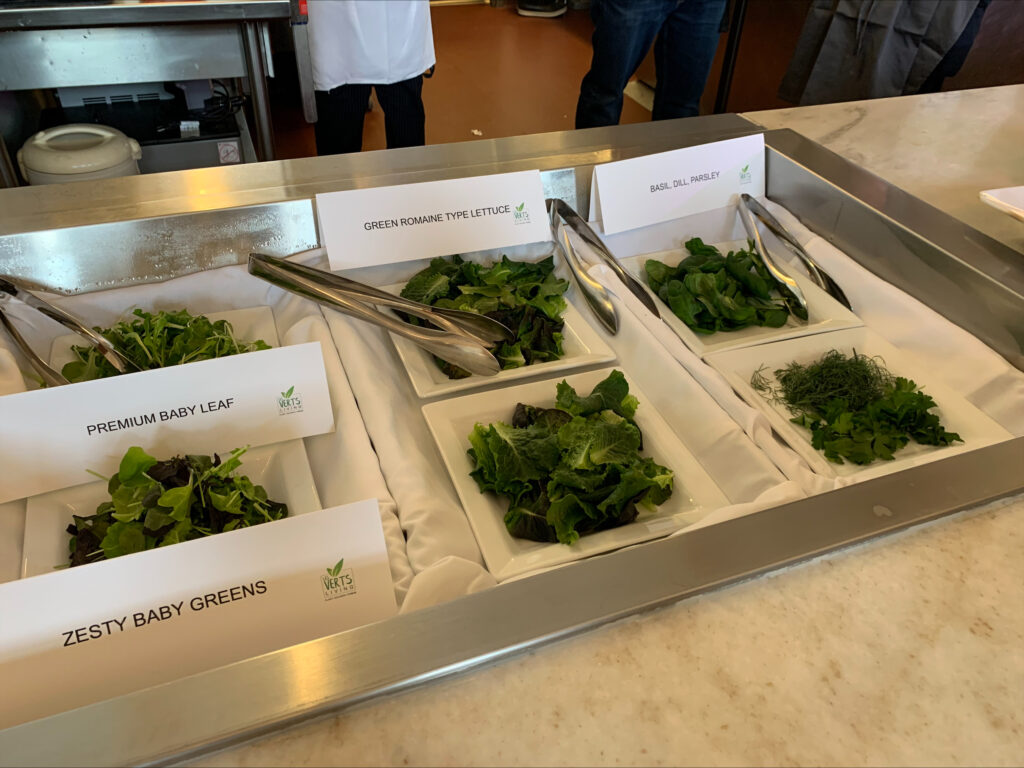

For example, the award-winning Prairie Research Kitchen (PRK) has partnered with Protein Industries Canada (PIC) and the Manitoba Métis Federation (MMF) to explore agri-food opportunities and address barriers to food security in rural and remote communities in Manitoba.

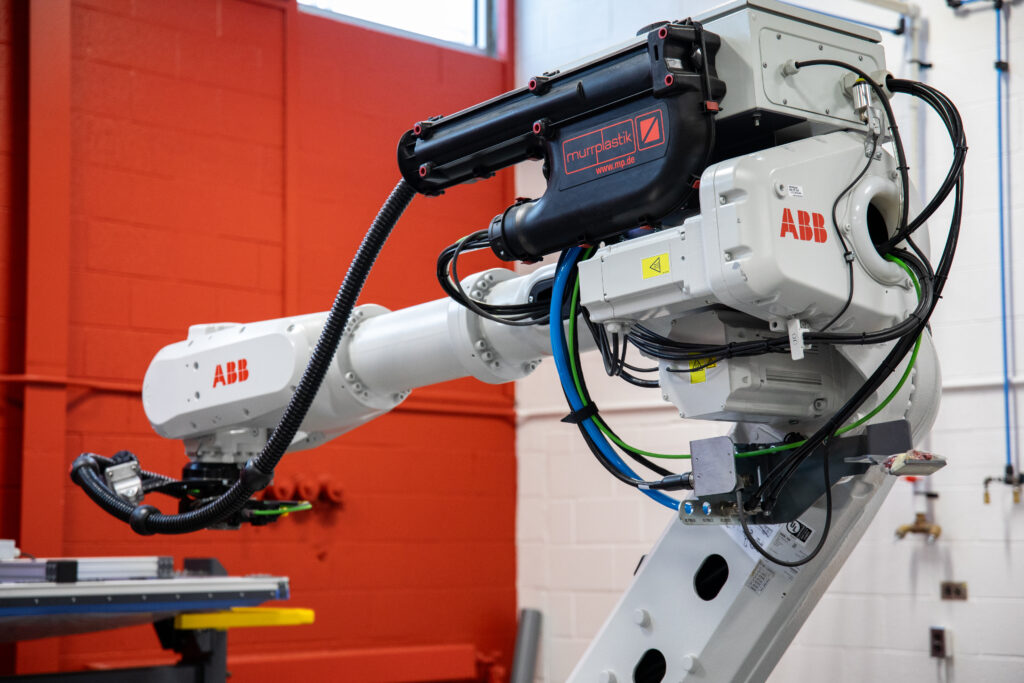

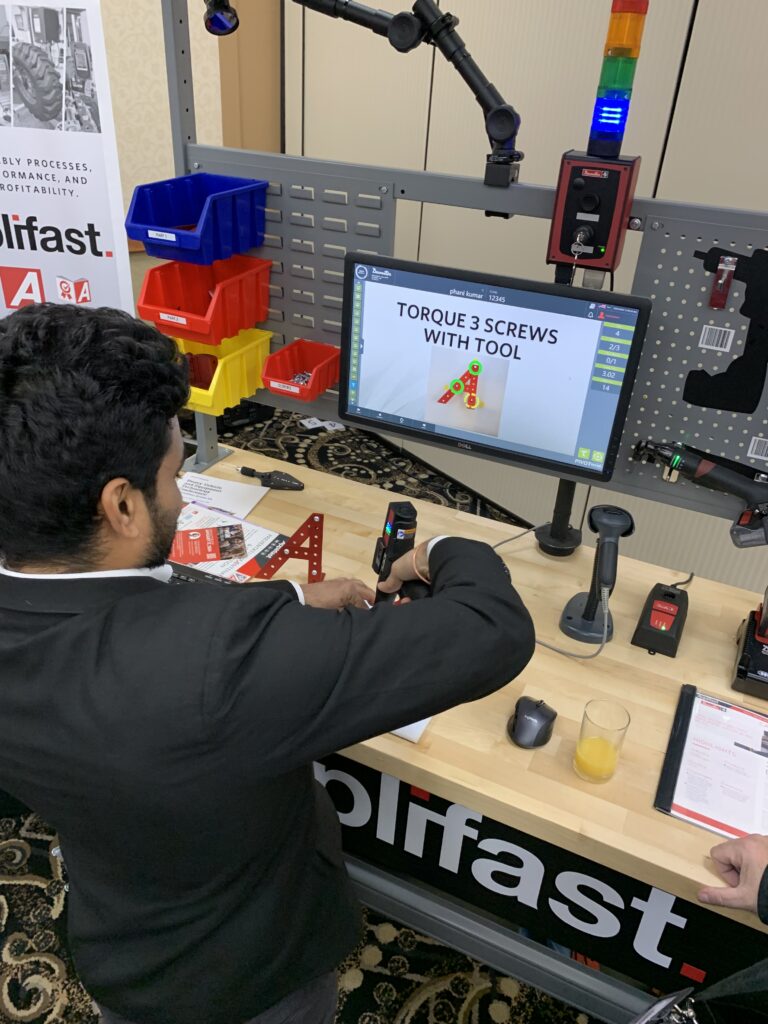

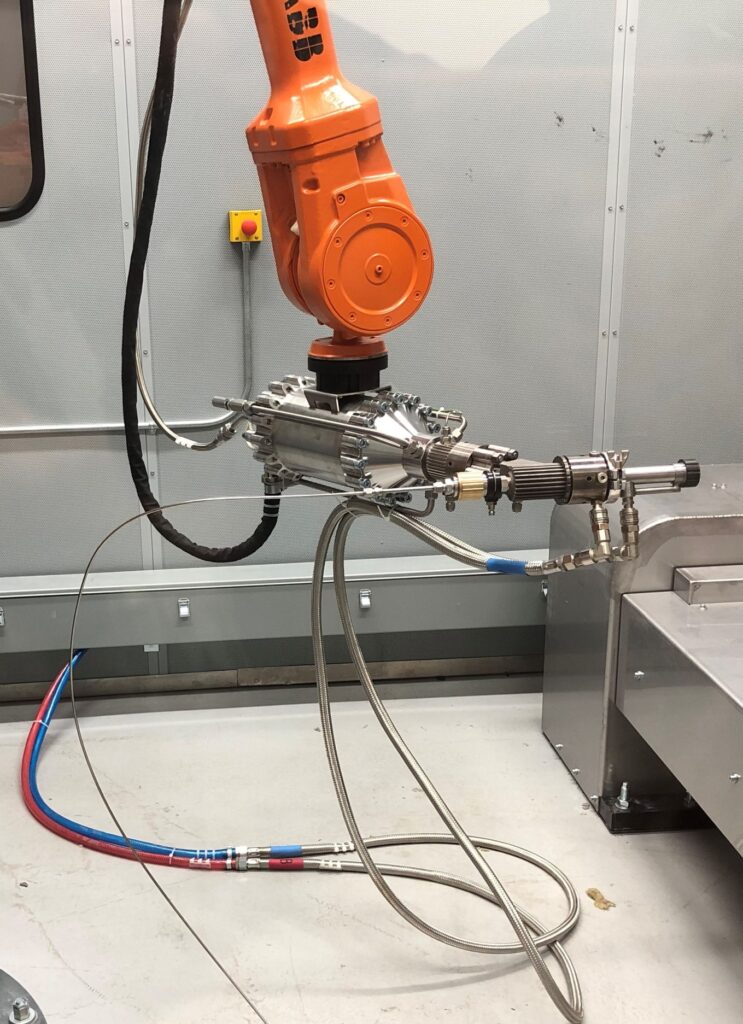

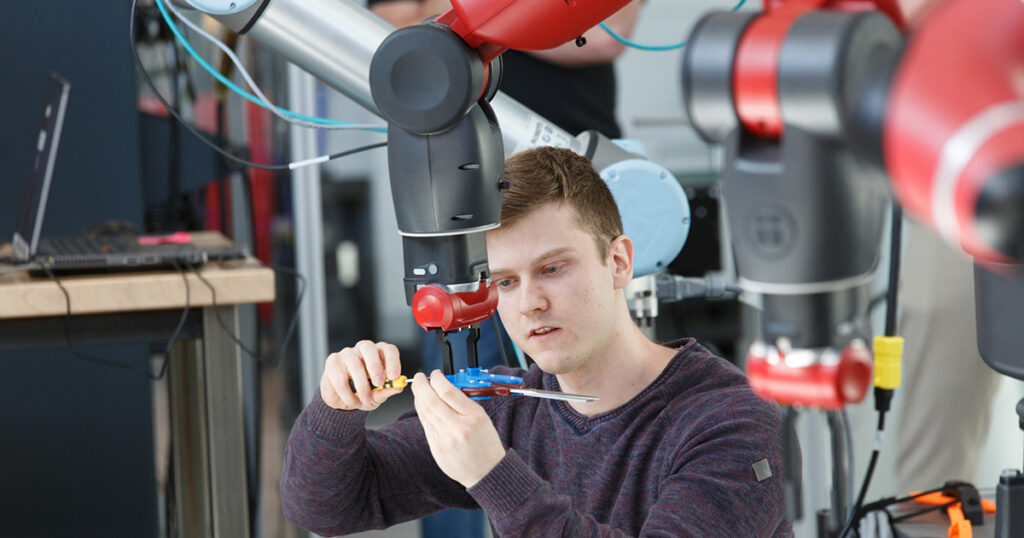

The Centre for Automation and Manufacturing Technology Transfer (CAMTT), located at the Polytech’s Price Institute of Advanced Manufacturing and Mechatronics focuses on transitioning to Industry 4.0 technologies like robotics, automation, and AI.

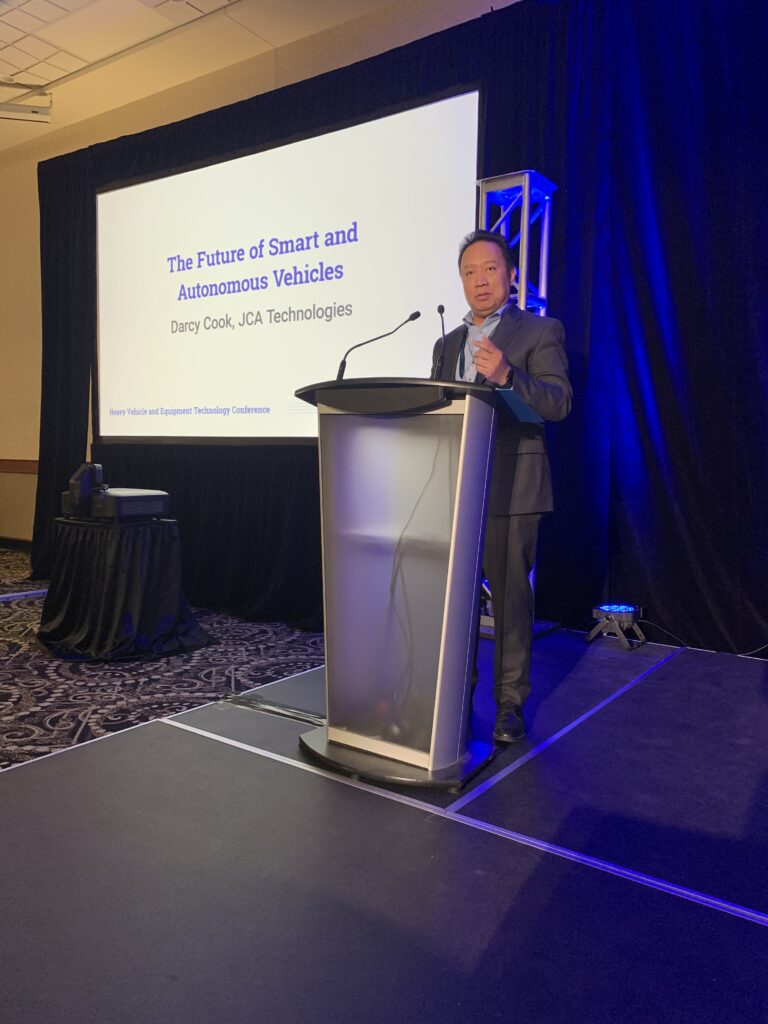

From testing heat pumps to developing a diesel-to-electric conversion kit for school buses, research teams at the Building Efficiency Technology Access Centre (BETAC) and Vehicle Technology & Energy Centre (VTEC) work with various partners to demonstrate how electrification can save energy and support a greener, more sustainable future.

While RRC Polytech’s Technology Access Centre for Aerospace and Manufacturing (TACAM) has developed unique non-destructive inspection capabilities to support additive manufacturing quality assurance, aerospace composite evaluation, and even fire investigations in Manitoba. TACAM is also home to the province’s first full-scale Laser Powder Bed Fusion (LPBF) system, advancing high-quality prototyping, process optimization, and sustainable tooling innovations for companies such as Precision ADM and Dimatec Inc.

“Through an incredible breadth of applied research collaborations, we’re solving real-world problems for our partners at all stages, from growth and productivity to adopting new tech and creating more sustainable processes – all while training tomorrow’s workforce to be more adaptable and embrace emerging technology,” said Dr. Jolen Galaugher, Executive Director of Research Partnerships & Innovation at RRC Polytech.

“Our ongoing and determined efforts to build networks that share knowledge and resources will continue to increase our capacity to lead innovation in Manitoba and beyond, driving economic growth and prosperity for everyone.”

Learn more at rrc.ca/research.

About the Rankings

Re$earch Infosource annually ranks Canada’s top research colleges based on performance metrics such as research income, partnerships, and completed projects. Institutions are categorized by size to ensure accurate comparisons. RRC Polytech consistently ranks among the top performers in the medium-tier category, earning recognition for its research excellence, innovation, and industry impact.

Read more on this year’s theme Research for Canada’s future and the future of Canadian research at Canada’s Innovation Leaders 2025