RPI’s 20 Stories for 20 Years – Lab to Market Funding

To demonstrate the impact that applied research projects make on all Manitobans, we present RPI’s 20 Stories for 20 Years. A compilation showcasing successful partnerships from the past and the present, with a constant focus on the future.

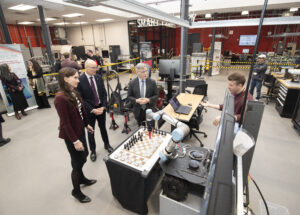

On January 15, 2025, the Government of Canada announced that RRC Polytech has been chosen to lead a national network of post-secondary institutions and collaborative partners to bring more academic research ideas to reality, support Indigenous business and drive economic growth.

As part of a national innovation strategy to increase entrepreneurship and research commercialization across Canada, the College has been awarded $24.1 million in federal funding over five years through a Lab to Market grant — becoming one of four network leaders to share in a total investment of $95.3 million.

Administered by the Natural Sciences and Engineering Research Council of Canada (NSERC), in collaboration with the Canadian Institutes of Health Research (CIHR) and the Social Sciences and Humanities Research Council (SSHRC), this is the largest tri-council grant ever awarded to or led by a college in Canada.

“For over 20 years, RRC Polytech has been solving industry problems and training tomorrow’s future leaders through applied research, and today we are honoured to continue to build on our strengths as a polytechnic and lead this collaborative, nation-wide network through the largest ever tri-council investment in a college,” said Fred Meier, RRC Polytech’s President and CEO.

“Our shared goal is to find solutions for the challenges that all Canadians are facing. This network combines the unique abilities of researchers at colleges and universities and connects them directly with industry and community to accelerate innovation.”

The College-University Lab to Market Network for Entrepreneurship and Research Commercialization spans eight regional hubs from B.C. to Nova Scotia and brings together 38 post-secondary institutions, along with other collaborators — including RRC Polytech’s Mittohnee Pogo’ohtah, one of three Indigenous hubs.

The support of Indigenous business growth is a foundational objective. Tailoring mentorship and resources to support Indigenous entrepreneurs while ensuring all research respects the principles of OCAP® (Ownership, Control, Access and Possession) is a shared goal that differentiates this network from other proposals that were considered.

Another unique element is including both colleges and universities, as they traditionally take a different approach to research. The network is designed to maximize the strengths of all contributors.

“Canada is home to world-class researchers, who generate ground-breaking technologies and innovations, and they need support to successfully commercialize their work,” said the Hon. François-Philippe Champagne, Minister of Innovation, Science and Industry. “Through these networks, researchers will receive the support they need to bring their innovations to market, benefiting communities from coast to coast to coast.”

Canadian researchers continually make discoveries with extraordinary potential across all sectors of the economy and society, but additional guidance and support is required for their ideas to become the next great products and processes.

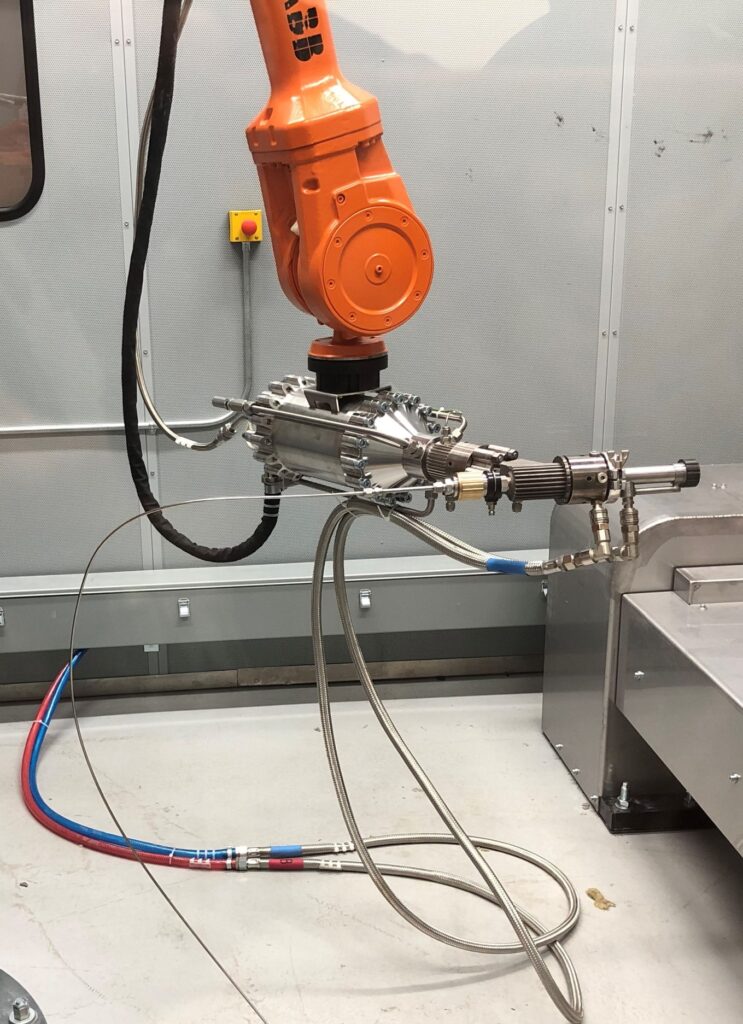

The infrastructure and expertise in industry-facing applied research found at Canada’s colleges and polytechnic institutions is critical for translating university-led academic research into innovation for the market and community users.

“This investment is a significant step in supporting Canadian researchers by giving them the tools, resources and support they need to turn their ideas into real-world solutions,” said the Hon. Terry Duguid, Minister of Sports and Minister responsible for Prairies Economic Development Canada, who was at RRC Polytech’s Notre Dame Campus to make the announcement.

“By connecting academic research with industry, we are helping to create new opportunities for innovation and economic growth across Canada.”

The new network will provide researchers with what they need to transfer scientific, social and service innovation to market or to community users. This support includes the sharing of best practices, digital resources to enhance awareness and knowledge of commercialization processes, mentorship and business coaching, financial assistance and access to an established Canada-wide network of Technology Access Centres.

RRC Polytech’s strong reputation for collaboration, central location and commitment to deepening partnerships and Truth and Reconciliation made it a natural fit to lead the network — another first, considering its size and scope.

“The college, university, community and industry partners in this initiative are the links in a chain of innovation and entrepreneurialism,” said Dr. Jolen Galaugher, RRC Polytech’s Executive Director, Research Partnerships and Innovation.

“By working together to ramp up productivity through the commercialization of Canadian research and IP, we’ll enhance our global competitiveness and positively affect all aspects of life for Canadians — economic, social or environmental.”

The Lab to Market initiative provides stable, long-term funding for all disciplines within the natural sciences, engineering, the social sciences, the humanities and health. RRC Polytech will immediately begin building capacity to lead its network of participants dedicated to fostering an entrepreneurial ecosystem that accelerates the economic and societal impact of Canadian research.

“Lab to Market grants bridge the gap between research ideas and their translation into economic and social innovation,” said NSERC President Alejandro Adem. “I can’t wait to see the results that will emerge from this new initiative.”

Co-applicant institutions:

British Columbia Institute of Technology, Cégep de Sherbrooke, Cégep de Thetford, College of the North Atlantic, Humber Polytechnic, Lethbridge College, Loyalist College of Applied Arts and Technology, MacEwan University, Mohawk College of Applied Arts and Technology, Mount Saint Vincent University, New Brunswick Community College, NorQuest College, Northern Alberta Institute of Technology, Northwestern Polytechnic, Nova Scotia Community College, Olds College, Red Deer Polytechnic, Saint Mary’s University, Saskatchewan Indian Institute of Technologies, Saskatchewan Polytechnic, Selkirk College, Southern Alberta Institute of Technology, University College of the North, University of Alberta, University of Lethbridge, University of Manitoba, University of Regina, University of Saskatchewan, United College – University of Waterloo, Western University, Yukon University

Collaborating partners:

MTA, NorthForge, Mitacs, Polytechnics Canada, Tech Access Canada, C2R2, Applied Pharmaceuticals Innovation, Edmonton Regional Innovation Network, CARIN, Calgary Innovation Coalition, Innovation Saskatchewan, Cultivator powered by Conexus, Synchronex, Axelys, Springboard Atlantic, Atlantic Colleges Atlantique