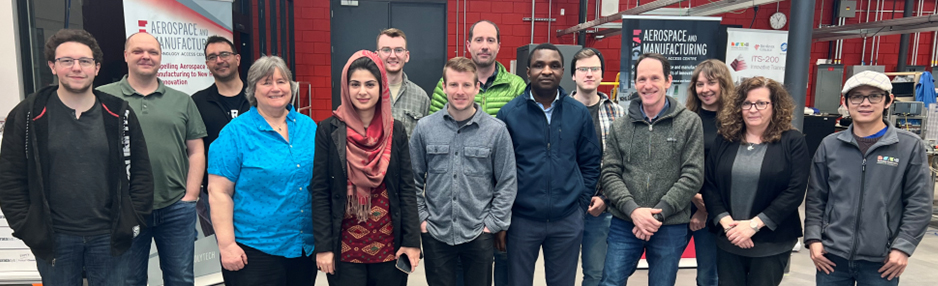

The Technology Access Centre for Aerospace and Manufacturing (TACAM) is a conduit for innovation, supporting the aerospace and manufacturing sectors by providing access to technological assets, applied research expertise and specialized training.

Access more than $37M worth of capital assets.

The Technology Access Centre for Aerospace and Manufacturing (TACAM) connects you with cutting edge, highly specialized facilities, equipment and expertise — right at the heart of one of Canada’s major aviation, aerospace and manufacturing centres.

With TACAM, you have access to the following facilities: Smart Factory, Gene HAAS Innovation Lab, Centre for Aerospace Technology & Training (CATT), Composites Model Factory, and Centre for Non-Destructive Inspection (CNDI). We also have flexible work options to come to you and make the service happen on your site or remotely.

Located at RRC Polytech’s Notre Dame Campus in the Skilled Trades Technology Centre (STTC).

The Smart Factory is an applied research space, experiential learning facility, and technology demonstration site that showcases emerging technologies.

The facility allows RRC Polytech students to gain hands-on experience working with the latest tech in a factory setting, while providing Manitoba companies with access to state-of-the-art equipment, instructors, researchers and students.

Located at RRC Polytech’s Notre Dame Campus.

The Gene HAAS Innovation Lab is the College’s centre for applied research and skills development in Computer Numerical Control (CNC) operations, Quality Analysis (QA) dimensional measurements, kanban or pull-based manufacturing systems, rapid-change tooling, and customized production.

Co-located at StandardAero facility, and supporting aerospace and manufacturing organizations.

The Centre for Aerospace Technology & Training (CATT) provides students, faculty and aerospace and manufacturing organizations with access to advanced technologies and equipment you’ll find nowhere else.

Co-located across RRC Polytech and at Magellan Aerospace, Winnipeg.

The Centre for Non-Destructive Inspection (CNDI) is home to the only Laser UT System of its kind outside of Lockheed Martin in the United States.

CNDI is the only place where organizations in Manitoba and beyond can access this technology, along with expert operators, to work on innovation and research projects such as developing/evaluating new components and processes, working with new materials, developing new products, and more.

The CNDI facility also contains a productive workspace and training area located adjacent to the LaserUT® system and control room.

Located at RRC Polytech’s Stevenson Aviation and Aerospace Campus.

The Composites Model Factory replicates an aerospace composite manufacturing facility. Located at Winnipeg James Armstrong Richardson International Airport and at Southport, Manitoba, we are at the heart of one of Canada’s major aviation and aerospace centres.

Note: We also have additional composites capabilities at our Notre Dame Campus.

TACAM has many years of experience working with regional companies, fostering innovation in the manufacturing and aerospace industries. It has a multidisciplinary team and TACAM experts have been actively undertaking applied research activities at RRC Polytech since 2002.

Janfizza oversees TACAM and provides strategic direction to the team leading towards technological advancements in aerospace and manufacturing. She holds a Ph.D. in Electronic Engineering from South Korea and has experience of leading industrial partnerships in aerospace and energy systems. She is the author of 14 research articles published in several international journals and conference proceedings. Her research interests include global sustainability, smart machines, autonomous robots and industrial IoT.

jbukhari@rrc.ca | 204.631.3430

Johanne has several years of experience performing administrative duties supporting staff and management teams and interacting with general public and political entities. Prior to joining TACAM, she provided admin support to senior leadership at Elections Manitoba and Manitoba Hydro as well.

jbergeron@rrc.ca | 204-632-3770

With an MBA and over 25 years of experience in the aerospace industry, Mike has made significant contributions to leading organizations such as Bombardier and Honeywell. A proud Canadian Armed Forces veteran, Mike brings a unique blend of strategic insight, technical expertise, and leadership skills to every project. His dedication and service have not only shaped his professional journey but also continue to inspire those around them.

msevigny@rrc.ca | 431.276.2646

Allan has been with TACAM since 2014. He coordinates training projects with industry clients, primarily in the aerospace sector. He has 23 years of experience in the Aerospace Manufacturing Industry. Prior to joining TACAM, he worked at Boeing Canada Technology Ltd and Magellan Aerospace in different roles.

Sarah specializes in Automation and Robotics. She is a graduate of the Electrical Engineering Technology program at Red River College Polytech. Her expertise includes systems integration and programming of various industrial processes based on programmable logic controllers (PLC) and supervisory control and data acquisition (SCADA) systems.

sjhodgson@rrc.ca | 204.632.2292

Ryan oversees applied research initiatives at TACAM. He is a seasoned Mechanical Engineering Technologist with over 15 years of experience in mechanical design, finite element analysis (FEA), and 3D printing. He is proficient in CAD modeling, FEA optimization, and Additive Manufacturing.

rcummine@rrc.ca | 204.632.2456

Gbenga specializes in Materials Engineering. He earned his doctorate from University of Manitoba in Additive Manufacturing of Aerospace Materials. His research interests include metal additive manufacturing, cold spray, welding, composite processing and non-destructive X-ray computed tomography (CT) inspections.

gasala@rrc.ca | 204.632.2030

Turker is a mechanical engineer with expertise in reverse engineering, mechanical design focusing on robotic simulation, robot programming and integrating industrial automation equipment for custom applications. He is a certified ABB trainer and teaches certification courses offered to industry clients through TACAM for ABB robots.

tsengoz@rrc.ca | 204.632.3433

Michael is a machinist with over 30 years experience in general manufacturing, precision CNC machining, CNC programming, aerospace manufacturing, aerospace overhaul and repair, oilfield and mineral exploration tools, mold making, tool and die, quality assurance, CMM programming as well as training and educational instruction. The courses taught at University College of the North include Blueprint Reading, Drafting, Computer-aided Design etc.

Vui Mai specializes in non-destructive inspection using X-ray Computed Tomography & Thermography. He is also a Cisco certified network associate who is managing TACAM’s industrial network. He holds a degree in Petroleum Engineering and has worked in the oil and gas industry for 11 years.

vnguyen80@rrc.ca | 204.632.3093

Riley specializes in electronics. He graduated from Red River College Polytech as Electronic Engineering Technologist. His expertise include embedded firmware development, software application development, robotic integration and printed circuit board design and development.

rcornelius34@rrc.ca | 204.631.3358

Kevin specializes in electronics circuit design, prototyping and analysis, embedded firmware and smartphone application design and development design. He graduated from Red River College Polytech as Electronic Engineering Technologist and since then he has been actively participating in applied research activities at TACAM.

Noah specializes in mechanical design and advanced manufacturing. He graduated from Red River College Polytech as Mechanical Engineering Technologist and since then he has been with TACAM participating in applied research projects in collaboration with industrial partners.

Devin specializes in instrumentation and control. His ongoing research activities focus primarily on automation and robotics, including industrial controls, collaborative and industrial robots, and autonomous mobile robots.

Adam brings over 15 years of industry experience as a mechanical design engineer. He holds a doctorate in mechanical engineering from the University of Manitoba with expertise in advanced finite element methods and computational fluid dynamics for numerical simulation and analysis of phase transformation and multiphase flow.

Ryota specializes in mechanical and materials engineering. He has experience in Design for Additive Manufacturing (DfAM), process development, mechanical testing and materials characterization, metrology, and quality assurance.

He graduated from RRC Polytech after his master’s degree in materials science from Osaka University.

The Technology Access Centre for Aerospace and Manufacturing (TACAM) is a part of the Natural Sciences and Engineering Research Council of Canada’s (NSERC) Technology Access Centre (TAC) program. TACs help local companies, particularly small- and medium-sized enterprises, become more productive and innovative by providing them with ready access to college expertise, technology and equipment.

TACAM is funded in part by the Natural Sciences and Engineering Research Council of Canada’s (NSERC) College and Community Innovation Program.

TACAM is also a proud member of Tech-Access Canada.

TACAM collaborates with a strong network of organizations, including sector councils and provincial technology service providers to leverage collective capability for industry. Key organizations whose involvements have been and will continue to be advantageous in complementing TACAM’s capabilities include:

RRC Polytech campuses are located on the lands of Anishinaabe, Ininiwak, Anishininew, Dakota, and Dené, and the National Homeland of the Red River Métis.

We recognize and honour Treaty 3 Territory Shoal Lake 40 First Nation, the source of Winnipeg’s clean drinking water. In addition, we acknowledge Treaty Territories which provide us with access to electricity we use in both our personal and professional lives.