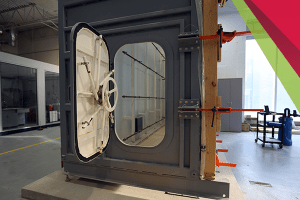

The Building Envelope Technology Centre (BETAC) houses a 12’ by 12’ air, water and structural (AWS) chamber that accommodates the construction and testing of wall and window assemblies to the following standard test methods:

| ASTM E283 | Standard Test Method for determining rate of air leakage through exterior windows, curtain walls and doors under specified pressure differences across the specimen |

| ASTM E1186 | Standard practices for air leakage site detection in building envelopes and air barrier systems |

| ASTM E330 | Standard Test Method for structural performance of exterior windows, curtain walls and doors by uniform static air pressure difference |

| ASTM E1105 | Standard Test Method for field determination of water penetration of installed exterior windows, skylights, doors and curtain walls by uniform or cyclic static air pressure difference |

| ASTM E331 | Standard Test Method for water penetration of exterior windows, skylights doors and curtain walls by uniform static air pressure difference |

AWS testing takes what can be costly guesswork out of the process of enhancing the building envelope. BETAC’s AWS chamber is intended to stimulate innovation in the design and construction of building envelopes. It allows building envelope details, windows, and doors to be evaluated for airtightness, water penetration, and structural deflection – prior to their use in actual construction. This means faster adoption of new building envelope components. Equally important, building professionals and students can participate in timely training activities that will increase the use of best practices for design and construction.

BETAC’s AWS chamber was put to the test in 2017 when a mock-up of the wall of RRC Polytech’s Skilled Trades and Technology Centre (STTC) was constructed and subjected to quantified testing – it’s first commercial use.

STTC is a state-of-the-art, $60-million facility that boosts skilled trades training at RRC Polytech’s Notre Dame Campus by 30%. The AWS chamber is in the Centre for Applied Research in Sustainable Infrastructure (CARSI). The chamber’s location allowed for testing of airtightness, structural integrity, and static water penetration within controlled conditions. The STTC mock-up wall easily passed its airtightness test and minor areas of improvement were identified to minimize water penetration.

The testing allowed for improvements to wall design to limit air and water infiltration on the STTC building. Air and water valves can be adjusted to test structures and materials under a range of calibrated pressures.

“Everything worked great. It’s very easy to correct problems. Having the ability to go inside the chamber is very rare and gives us huge advantages.” BETAC Research Consultant Kevin Knight.

The chamber is now available for design and construction firms to test samples of their walls, or for firms to test new products and materials so that problems can be identified and resolved prior to mass production or construction.

“This unique opportunity to verify design and constructability allowed the project team to proceed to construction with confidence.” Henry Bakker, Contract Administrator, Number TEN Architectural Group.