Get the applied and theoretical knowledge you need to build the environments of the future. Whatever the stage of your career, Red River College Polytechnic provides skills to fill in industry gaps, giving you access to innovative work — whether that’s in the urban jungle, alongside nature, or in future-forward laboratories.

Check out our latest full-time and part-time programs and apply or register today!

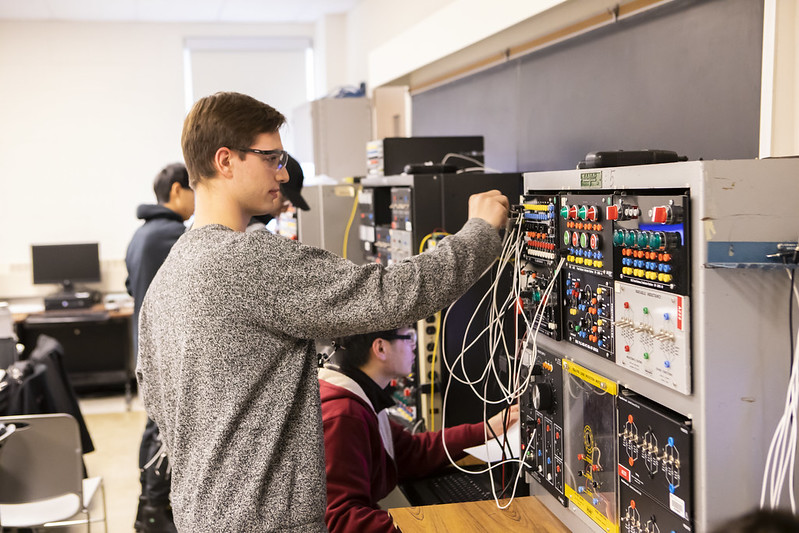

We offer enhanced learning opportunities and small class sizes to make sure you’re supported from day one.

Average recommendation rate among recent graduates; retrieved from the 2019-2020 RRC Polytech Graduate Satisfaction and Employment Reports.

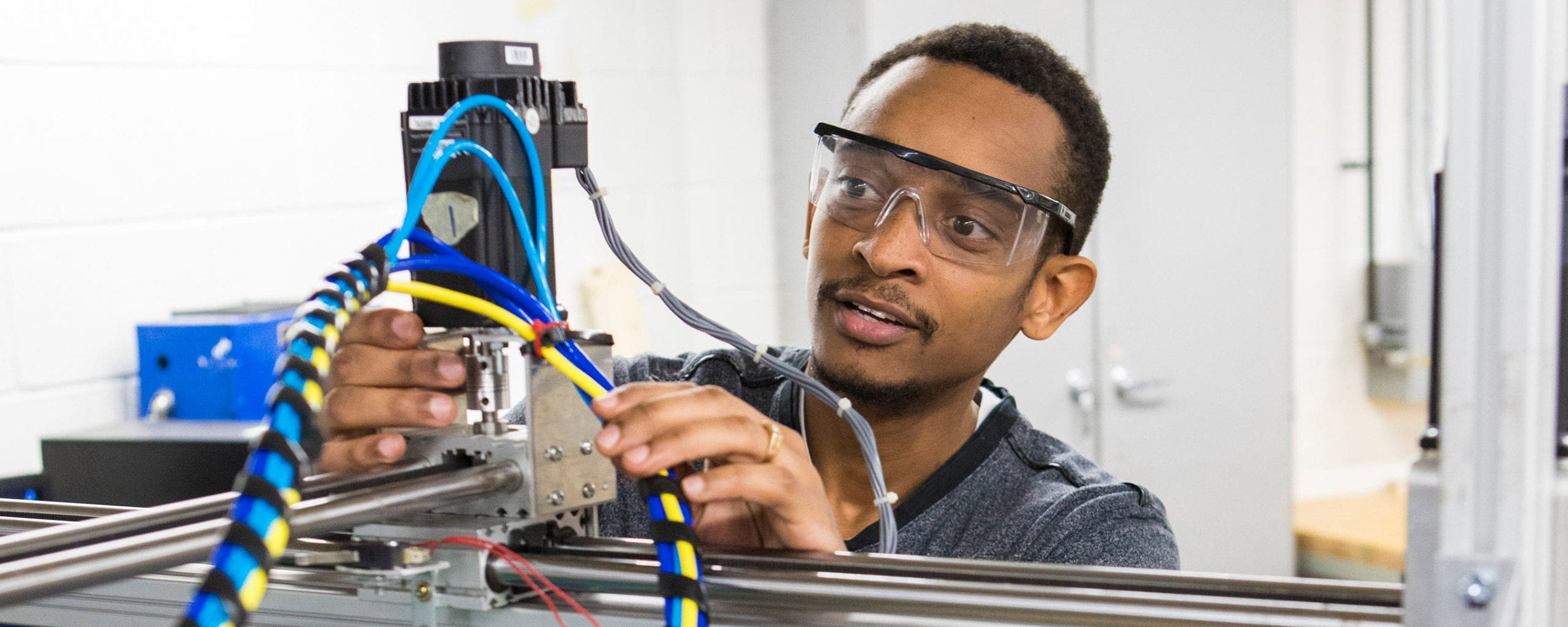

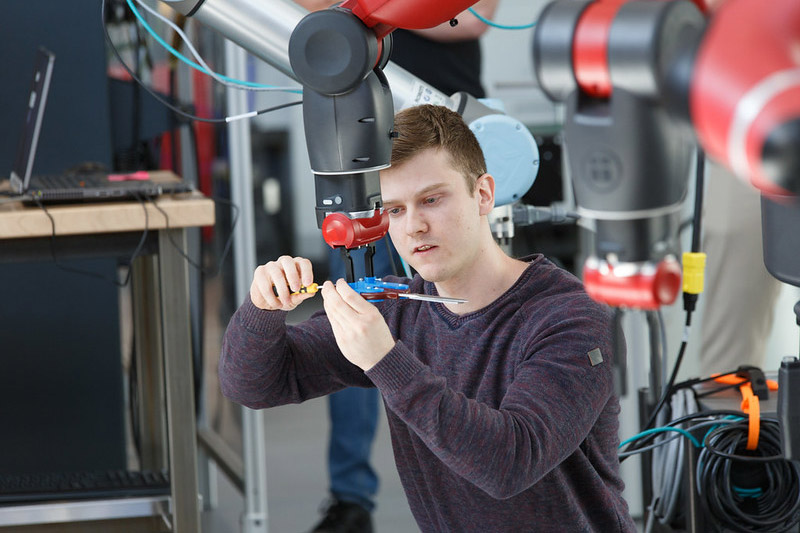

Our engineering and construction technology programs are designed to fill-in industry gaps and give you access to innovative work and experiences.

Average employment rate among recent graduates; retrieved from the 2019-2020 RRC Polytech Graduate Satisfaction and Employment Reports.

From designing and powering the places we live to creating a more sustainable world, you will gain the skills needed to jump-start your career.

Average satisfaction rate among recent graduates; retrieved from the 2017-2018 RRC Polytech Graduate Satisfaction and Employment Reports.

“When I got to Red River College Polytechnic I was nervous it would be a similar experience to my time at university, but I was wrong. Here, instructors know my name. They say hello in the hallways, they care about my grades, and they make time to answer all my questions — and I had a lot of questions. At RRC Polytech, the instructors take a personal interest in my success and work with me so I can succeed. Being here feels like I have my own private tutor for every class.”

Allison Enns, Site Coordinator, Akman Construction Ltd.

Graduate, Architectural/Engineering and Construction Management

RRC Polytech campuses are located on the lands of Anishinaabe, Ininiwak, Anishininew, Dakota, and Dené, and the National Homeland of the Red River Métis.

We recognize and honour Treaty 3 Territory Shoal Lake 40 First Nation, the source of Winnipeg’s clean drinking water. In addition, we acknowledge Treaty Territories which provide us with access to electricity we use in both our personal and professional lives.